URETEK FLOOR LIFT®

URETEK FLOOR LIFT®

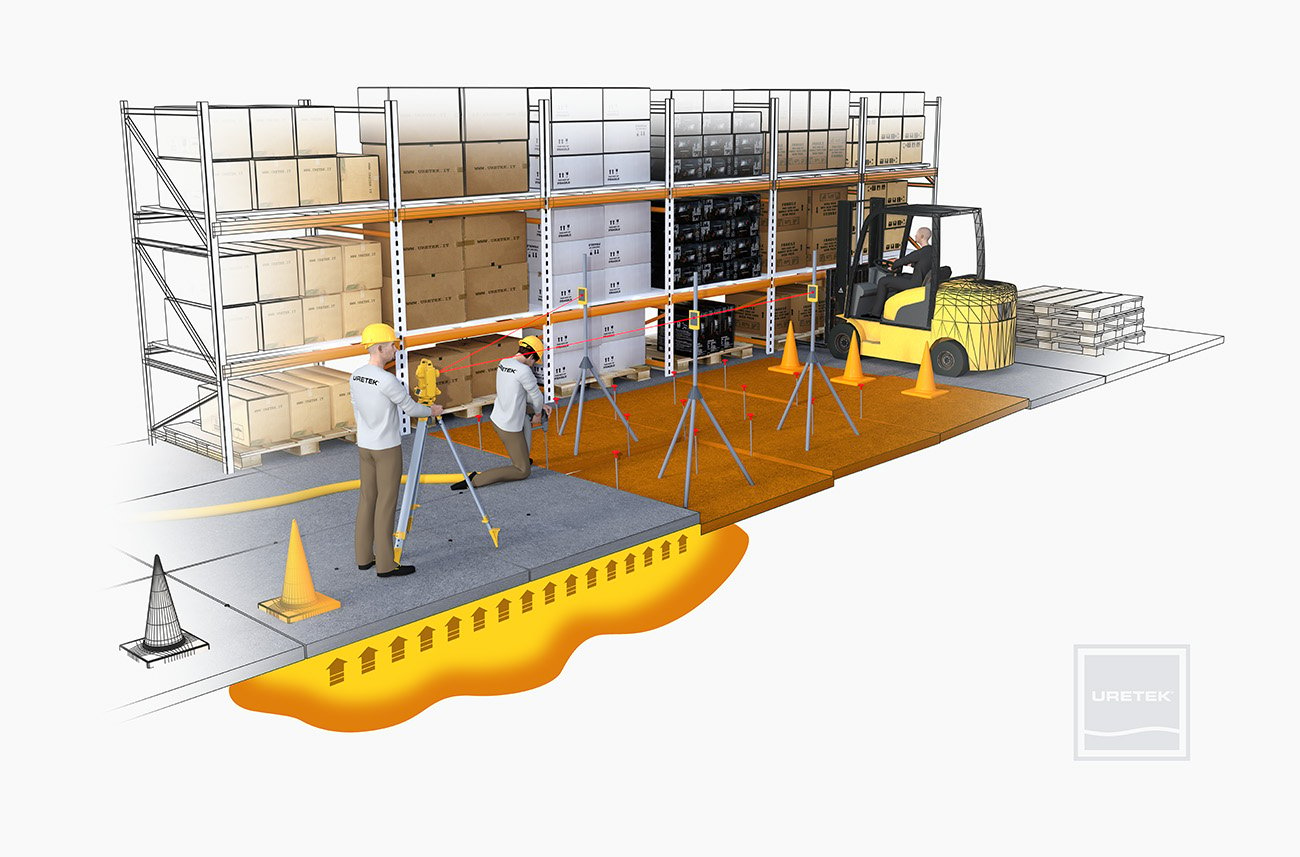

Injections of expanding resin under flooring

Our exclusive Floor Lift® technology stabilizes and lifts sunken flooring. We inject resin under the flooring and when the resin sets, its expansion compacts the subgrade, thereby lifting the floor.

The lift, which amounts to a few centimetres, is monitored continuously using laser systems.

When to use Uretek Floor Lift®?

- To recover the flatness of sunken flooring.

- For prevention, when restoring buildings on unstable terrain.

- To fix steps between slabs of industrial flooring.

- Whenever there is a load increase (reallocating areas).

The Advantages

- Efficient subgrade compaction

- Lifting from a few millimetres to several dozen centimetres

- Control using laser levels for millimetre precision

- Quick intervention without interrupting activities

- Does not dirty or release dust

- Quick work-site set-up

Where do we apply the

Uretek Floor Lift® method?

Commercial and industrial buildings

Our Floor Lift® technology causes practically no inconvenience. Our interventions are quick and generally done without interrupting work activities. For steps between slabs, we recover the original flatness.

Public buildings

We work without demolishing anything and with the utmost safety for the public. The buildings do not need to be closed, allowing normal activities to continue.

Roads – Motorways

With Uretek Floor Lift®, we stabilize roads, bridge slabs, and airport runways. The quick setting times of the resin allow the treated zone to be used immediately.

Private Houses

We treat lowered flooring in private houses, even in a single day, without having to evacuate the premises. The 6-mm holes drilled along the grout lines often mean the existing tiles can remain in place.

When necessary, the intervention is completed with deep injections using the Uretek Deep Injections® technology.

How the Uretek Floor Lift® technology works

We inject resin in its liquid state. In this state, it penetrates all the voids present under the flooring, before turning into a solid gel. The chemical reaction makes the resin expand. The lift occurs due to the pressure resulting from the polymerization, not due to the injection pressure. This polymerization pressure is enough to lift heavy objects such as machinery or full shelves. The resin is NOT biodegradable.

THE PROBLEM

Voids in the subgrade can lead to subsidence, damage, loss of planarity, and breakage in the joints in the pavement.

THE SOLUTION

We inject GeoPlus® resin into the subgrade through small holes.

THE RESULT

When it expands, the resin seals, compacts, and recovers the flatness of the flooring.

TECHNICAL SHEET

- Maximum swelling pressure: 10 MPa

- Resin density between 45 kg/m3 and 120 kg/m3 (sometimes even more)

- Lifting: up to 30 cm

- Expansion capacity of the resin under free expansion up to 30 times its initial volume

- Polymerization occurs even in wet environments

The Steps

Identification of underground utilities

Before drilling and when possible, we proceed by identifying the network of underground utilities that cross the work area.

Drilling

We generally drill holes with a bit diameter of 6 mm. The absence of dust, demolition, and vibrations mean we can work without evacuating the premises.

Insertion of the injection tubes

Inserted in the holes, they allow us to inject the URETEK® expanding resin.

Injection of the expanding resin

We make the injections using a gun in which the resin components are mixed.

Lifting

The resin penetrates and compacts the subgrade layer below the floor. Continuing with the injections, we lift the necessary areas.

Laser Monitoring

We carefully control the lift using a laser level.

Finishing

After lifting is complete, we finish the work by filling the holes used for the injections.

See how we have resolved issues

We are close to you and we work wherever in the world our professionalism is needed.

We are familiar with your area and bring with us multinational experience.