URETEK MICROANCHORS®

URETEK MICROANCHORS®

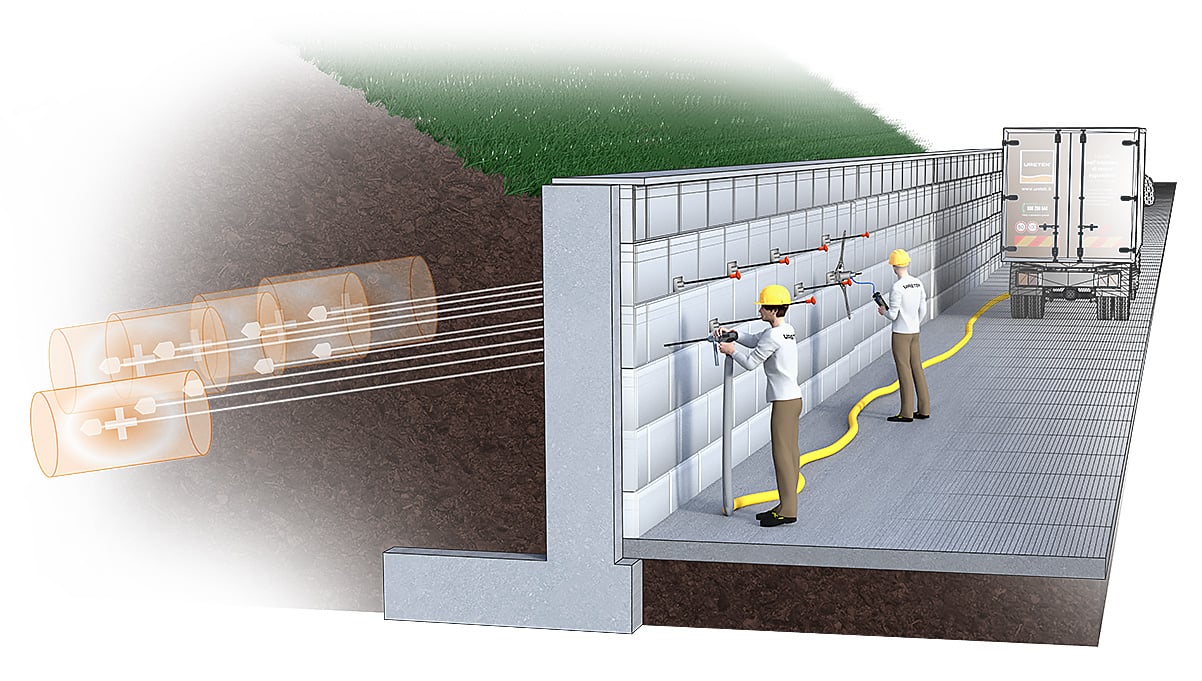

Stabilization of retaining walls

We have designed the exclusive Uretek MicroAnchors® technology to contrast ground thrust and avoid displacement and deformation of the terrain. We combine stainless steel anchors with injections of expanding resin for perfect consolidation.

When do we use Uretek MicroAnchors®?

These micro anchors are very versatile and particularly suitable for existing works, structures that are unable to support point-like loads and for which the intervention must be non-invasive and quick.

THE ADVANTAGES

- Less expensive than traditional technologies;

- Versatility: the equipment and materials can be transported by hand, allowing for interventions in demanding areas or tight spaces.

- Small diameter: we apply Uretek MicroAnchors® even to walls of a modest thickness or in a suboptimal state of conservation, which is not possible with traditional tie rods.

- Speed: the intervention is immediate and effective — up to 30 anchors per day.

- Non-invasive technology: no excavations, residue, or vibrations, and limited noise.

- Technical support: we support professionals in all phases of project design and implementation.

Where do we apply Uretek MicroAnchors®?

The MicroAnchors® technology is applicable to various structures, for example:

- Quays and ledges:Recovering lift due to subsidence of the soil

- New installations (e.g. pools): Increasing the lift of the terrain

- Heavy machinery: Increasing the lift of flooring for new installations

- Silos or large tanks: Increasing lift for new installations

- Warehouse expansions, new load-bearing structures: Increasing lift for new installations

- Stone boundary walls: Recovery of masonry binding agents

- Walls over underlying canals: Recovery of masonry binding agents

- Riverbank walls, piers, and embankments: Recovery of masonry binding agents

- Bowed/collapsed walls: Securing retaining walls

- Retaining walls with a road above (reinforcement): Securing retaining walls

- Bulkheads and containment walls (support): Securing retaining walls

- Retaining walls with installations above (pools, car parks, cisterns): Increasing the lift of retaining walls

- Retaining walls with installations above (lines, silos): Increasing the lift of retaining walls

- Retaining walls with installations above (roads): Increasing the lift of retaining walls

- Underpasses, culverts, tunnels: Retaining wall support

- Foundation soil for pipes, oil pipelines, and conduits (improvement): Reinforcement of excavation retaining walls

How the Uretek MicroAnchors® technology works

We install a series of micro anchors on the surface of retaining structures following a regular grid and inject expanding resin to stabilize the masonry. We use small portable equipment that can be moved and manipulated entirely by hand. The pumping equipment, resin, and generator are housed in an equipped truck, which may be parked up to 80 metres from the work site.

TECHNICAL SHEET

- Micro anchors

- Steel tubes 12 x 0.95 mm or stainless steel tubes 12 x 1.5 mm;

- Cables made of harmonic steel;

- Ferrule with 18-, 25-, 28-, or 32-mm diameter;

- CE marking.

- Uretek® Resin

- Reaction time: a few seconds

- Pressure up to 10 MPaA

The Steps

1. Drilling

We perform this phase quickly and little interference, using electric roto-percussion hand drills equipped with special small-diameter bits or small column probes for anchoring to the walls.

2. Implementation

We lay the micro anchors in the hole up to the design distance by hand or using an electric drill. We therefore create a cavity around the anchor head to ensure the space necessary for the resin to exit the head and the holes along the conduit.

3. Injection

We inject the expanding resin using a gun connected to the end of the steel tube of the micro anchors. The injection is regulated by one of our workers, who dispenses the amount of material envisaged in the project. In this way, we create a resistant bulb that solidifies in just a few seconds, allowing the tie rod to be stretched.

4. Immediate tensioning

We mainly stretch the rods using an adjustable mechanical system with suitable keys and controlled with a previously calibrated load cell. We fasten the micro anchors to the wall using a steel bushing equipped with fastening wedges.

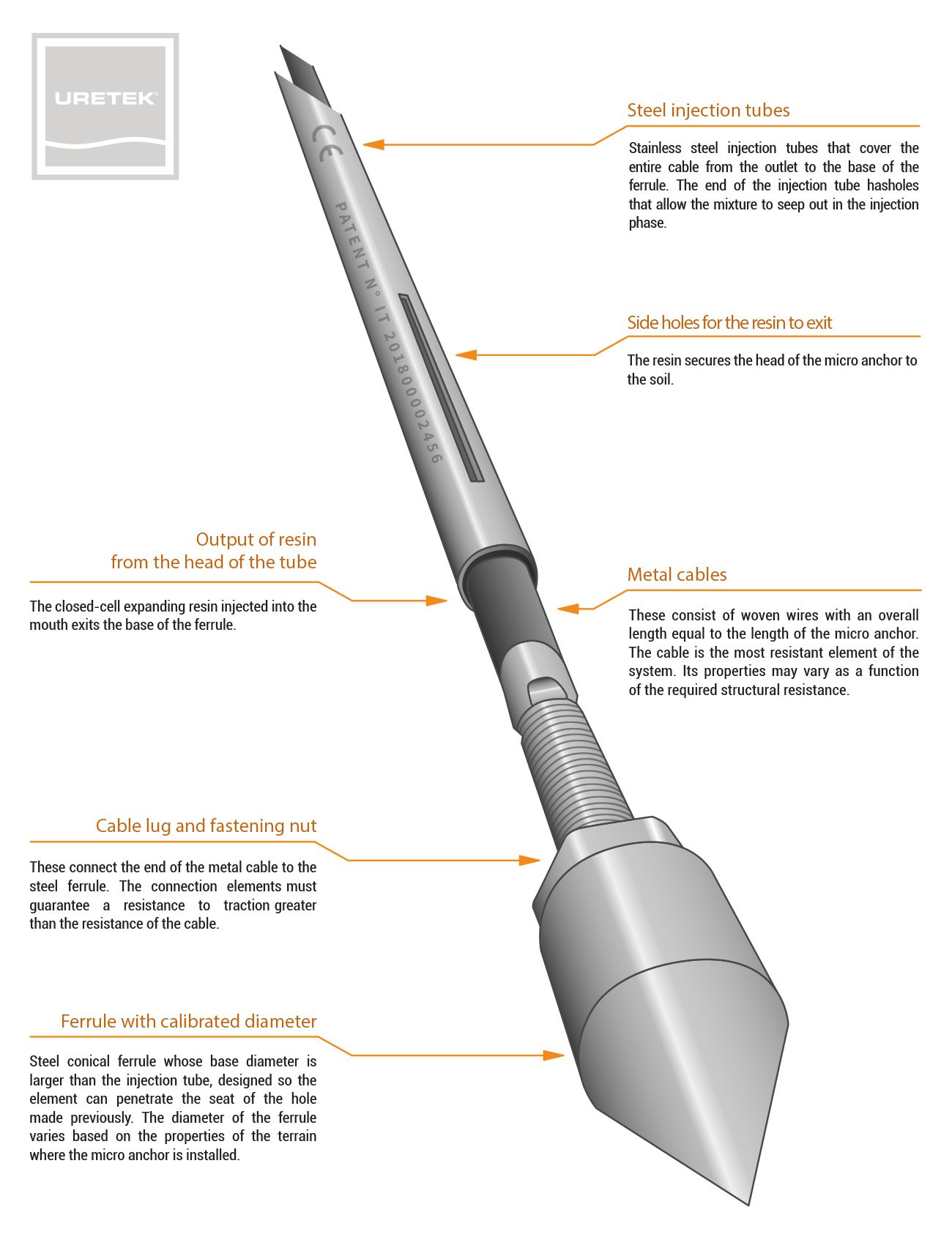

Structure of the micro anchors

The micro anchors consist of a set of partially pre-assembled rust-proof metal elements packaged in bundles and reels that can be handled entirely by hand.

Steel injection tubes

Stainless steel injection tubes that cover the entire cable from the outlet to the base of the ferrule. The end of the injection tube has holes that allow the mixture to seep out in the injection phase.

Side holes for the resin to exit

The resin secures the head of the micro anchor to the soil.

Output of resin from the head of the tube

The closed-cell expanding resin that we inject into the mouth exits the base of the ferrule.

Cable lug and fastening nut

These connect the end of the metal cable to the steel ferrule. The connection elements must guarantee a resistance to traction greater than the resistance of the cable.

Metal cables

These consist of woven wires with an overall length equal to the length of the micro anchor. The cable is the most resistant element of the system. Its properties may vary as a function of the required structural resistance.

Ferrule with calibrated diameter

Steel conical ferrule whose base diameter is larger than the injection tube, designed so the element can penetrate the seat of the hole made previously. The diameter of the ferrule varies based on the properties of the terrain where the micro anchor is installed.

See how we have resolved issues

We are close to you and we work wherever in the world our professionalism is needed.

We are familiar with your area and bring with us multinational experience.