URETEK CAVITY FILLING®

URETEK CAVITY FILLING®

Filling cavities and crawl spaces with injections of expanding resin and expanded clay

Our exclusive Cavity Filling® technology fills and compresses cavities without overloading the soil above.

When to use Uretek Cavity Filling®?

THE ADVANTAGES

- Perfect filling, also thanks to the high expanding force of the resin

- No shrinkage or plastic settling of the material, with complete filling and resistance of the cavity (prestressing the vault)

- Quick securing of areas at risk

- Immediately effective due to the quick-setting resin

- No interaction with sensitive materials

- No modification of water circulation, since the resin is injected into the upper part of the cavity

- Possible to excavate or drill into the resin/clay amalgam with conventional means.

- Cost saving

Where do we apply the

Uretek Cavity Filling® method?

Cavities

Basements, crawl spaces, underground tanks, artificial tunnels, or any cavity whose dimensions can be fully determined.

Gaps

Restoring the safety of flooring above crawl spaces.

Man-made cavities

Filling barrels or cisterns, and securing structures that rest on man-made or natural underground cavities. Instability of silos or underground cisterns due to the presence of cavities.

How the Uretek Cavity Filling® technology works

We fill cavities with expanded clay and then inject an expanding resin into the clay-filled volume to improve its resistance. We use light materials that do not overload the ground underneath. The expansion of the resin completely fills the upper part of the cavity. For damaged buildings above the cavity, we stabilize the soil between the cavity and the building using Uretek Deep Injections® technology.

TECHNICAL SHEET

- Expanded clay

- Density of the piled material UNI EN 13055-1: ≤ 4.5 kN/m³ (450 kg/m³)

- Friction angle ≅ 40°

- Water absorption UNI EN 13055-1: < 75%

- Deformation modulus: Md with Dr > 80%: ≥ 25 MPa (250 kg/cm²)

- Crushing resistance of the grains

- UNI EN 13055-1: > 1300 kPa (> 13 kg/cm²)

- Uretek® Resin

- Reaction time: a few seconds

- Elastic modulus similar to foundation soil: 10–180 MPa (100–1800 kg/cm²)

- Variable density depending on the expansion: 1–3 kN/m³ (100–300 kg/m³)

The Steps

1. Definition of the project

We make a preliminary study to define the size of the space (volume and shape).

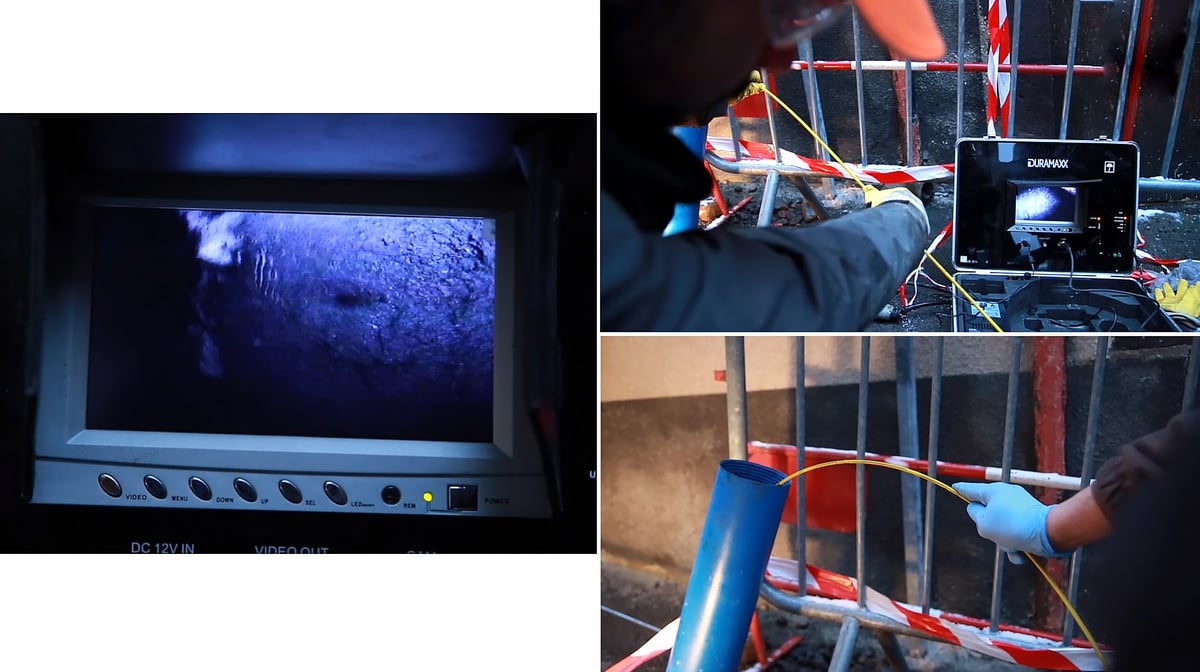

2. Initial drilling (if necessary, when the cavity cannot be directly accessed by the URETEK operator)

We drill holes with a diameter of 120 mm into the part to treat.

3. Filling with expanded clay

We fill the cavity with grains of clay. Using a flexible tube, we send the clay from the truck to the cavity using compressed air.

4. Secondary drilling (if necessary, when the cavity cannot be directly accessed by the URETEK operator)

We drill holes again, this time with a diameter of 12 mm to inject the resin. The grid of injection tubes varies depending on the depth of the work.

5. Injection of the expanding resin and its spread among the grains of clay

The expansion of the Uretek® resin ensures nearly continuous contact between the grains of clay and the inner walls of the cavity, with significantly greater filling compared to traditional techniques. We also saturate and prestress the vault. Polymerization is very fast because the resin sets long before it can flow to the bottom of the cavity.

See how we have resolved issues

We are close to you and we work wherever in the world our professionalism is needed.

We are familiar with your area and bring with us multinational experience.