URETEK MULTIPOINT®

HOW THE URETEK MULTIPOINT® INJECTION SYSTEM WORKS

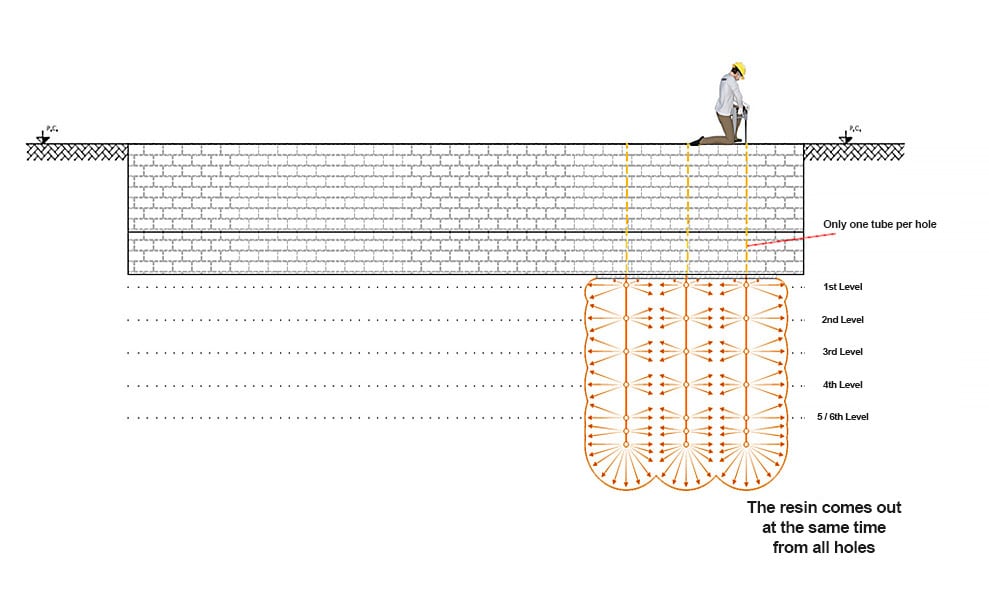

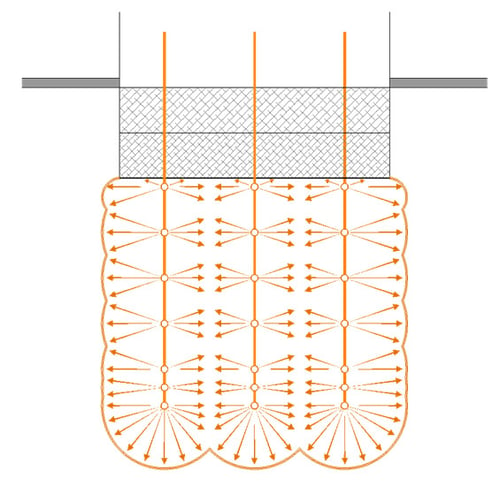

We recently combined the Deep Injections® technology with the widespread Multipoint® injection system, which involves the injection of resin through a tube with multiple holes on the sides (12–14) called ‘multiholes’, while the traditional system involves injections at multiple levels by means of a tube with an outlet only at the end.

We make injections intermittently, alternating the dispensing of the mixture with pauses of a predefined duration.

The experimentation began in early 2017 and ended in July 2018 with filing of the related patent (International patent application n ° WO2020 / 011414)

The strengths of the Uretek Multipoint® system

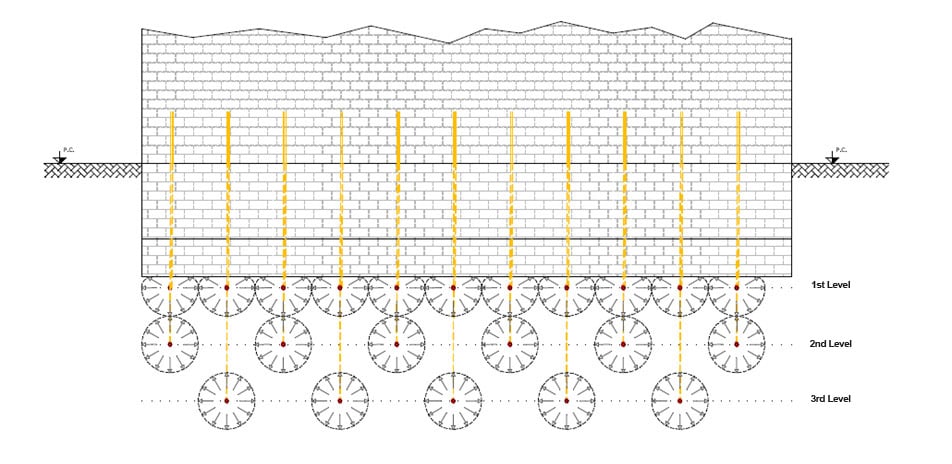

- Very dense, regular injection grids due to the high number of calibrated holes present along the tube.

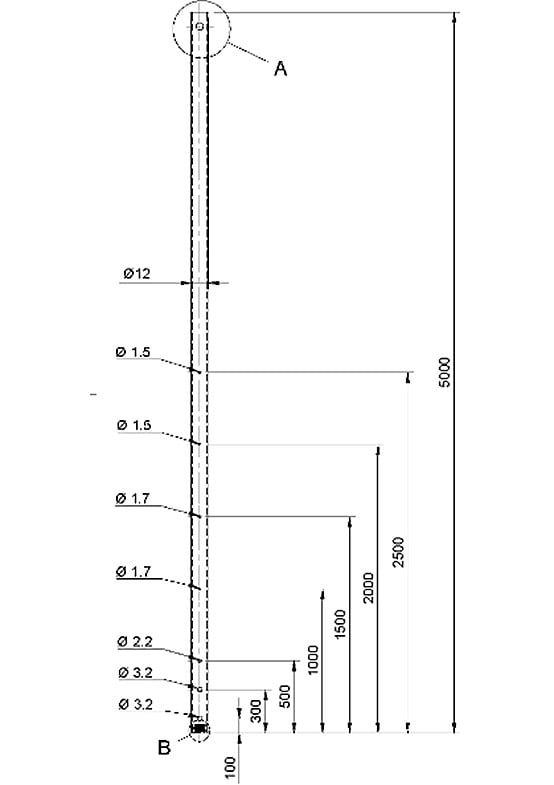

- Guaranteed uniform treatment. With the arrangement of the holes, which are calibrated and increase in size with depth, the resin exits from all holes simultaneously (12–14 holes per injection tube). It is therefore possible to define the flow from each hole by calibrating the openings made along the tubes.

- The resin is localized near the holes, preventing dispersion, that is, discontinuities in treatment, since the injections with a quick-set resin are made intermittently.

- The resin is injected at a pressure slightly higher than the resistance pressure of the soil, guaranteeing spread of the material even in volumes with low permeability.

Distribution of the injection grid and points where the resin spreads.

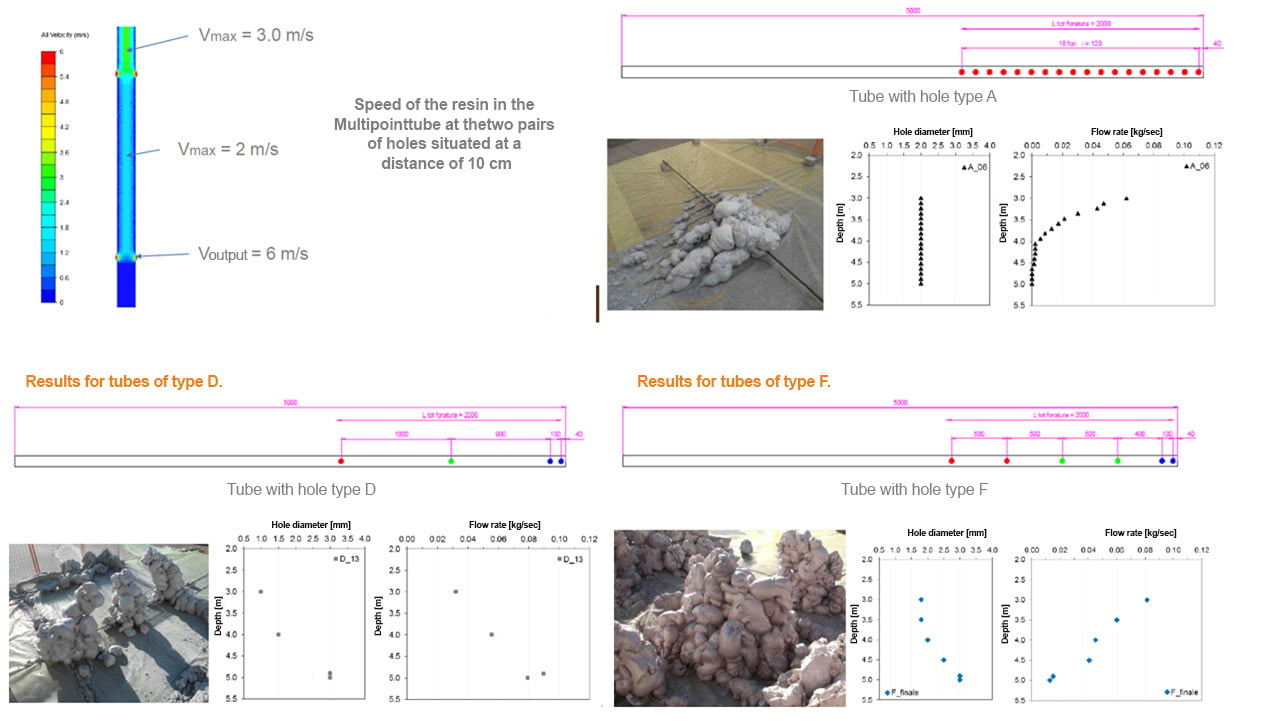

Since these resins have a given viscosity and rather short chemical reaction times, we have carefully calibrated all the parameters (injection pressure and volume, diameter and characteristics of the multihole tube, diameter and spacing of the holes along the sides) to even out and distribute the injection along the entire path.

Indeed, holes of the same diameter would lead to non-uniform (or impossible) injection, as shown in the following figures, which present the results of tests made with different tube hole configurations.

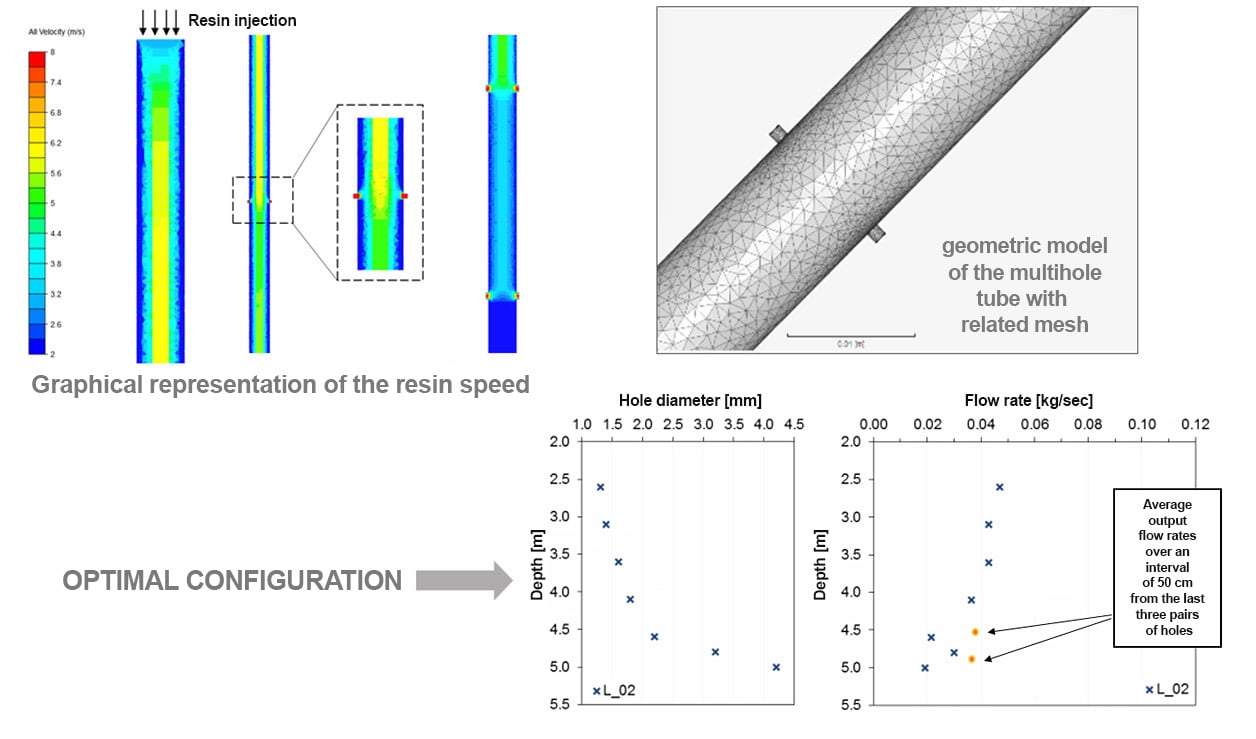

To design the tubes and optimize the injection process, we have developed mathematical models with the finite element method, assisted by Profs Manassero and Dominijanni at the Polytechnic University of Turin.

We studied and tested various hole spacing and diameter configurations to identify the best configuration for treating soil layers from 2 to 3 m deep.

Theoretical model of the flow of resin and experiments.

Theoretical model of the flow of resin, finite element grid, and representation of the best configuration.

Theoretical model of the flow of resin, finite element grid, and representation of the best configuration.

Spacing and diameters of the holes for treatment at a depth of 3 metres.

Spacing and diameters of the holes for treatment at a depth of 3 metres.

To treat greater depths, one could easily use overlapping injections from perforated tubes in series.

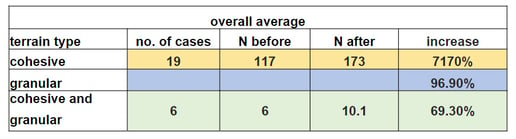

Experimentation in real situations was carried out over 33 interventions, 19 of which were in mainly cohesive soil, 8 in mainly granular soil, and 6 in ‘mixed’ (granular + cohesive) soil.

For immediate feedback (i.e. quick and not exhaustive) on the improvement of the soil, dynamic tests were made with a DPM penetrometer with a 30-kg hammer and 20 cm stroke, detecting the number of hits necessary to penetrate 10 cm with a 10-cm2 conical tip.

The results are summarized in the following table (C = cohesive, G = granular, GC = mixed).

Penetration test results

From the above, it is clear that the average increase in resistance (expressed as number of DPL hits) was +77.4%, with a maximum of +358% and a minimum of -15%, both in primarily cohesive soil. Although the DPL dynamic penetration data show some limitations in reliability when evaluating the geotechnical parameters, particularly in cohesive soil, the appearance of the same data before and after injection provide reliable data regarding the resistance of the terrain due to the injections along the vertical axes in question.

Ultimately, the URETEK MULTIPOINT® system allows for net improvement of the soil ‘continuously’ along the length of the tube, while maintaining the non-invasiveness of the intervention and creating drastic savings in extra work that would be necessary with other types of intervention such as subgrades with micro piles.

See how we have resolved issues

Traditional system with injections on multiple levels

Uretek Multipoint® system: expanding resin injections through a multihole tube