URETEK WATER BARRIER®

URETEK WATER BARRIER®

Injections of expanding resin and saturating gel to create waterproofing barriers

With dual action that combines an expanding resin and a specifically developed saturating gel, our exclusive Water Barrier® technology creates a waterproof barrier between the structure and terrain behind, eliminating the water within the structure itself.

When to use Uretek Water Barrier®?

- To counteract water infiltration that may seriously damage underground structures and make rooms unsuitable for use. By infiltration, we mean a copious flow of water such that the water penetrates and is visible within the structure.

This technology is used to treat:

- localized infiltration (usually along discontinuities)

- widespread infiltration (usually tied to construction deficiencies)

- masonry, foundation slabs, or flooring in reinforced concrete (minimum thickness 20 cm)

- stone or brick masonry (minimum thickness 30 cm)

The Advantages

- Quick application, 30 sq. m/day

- Inexpensive solution

- Immediately effective with visible results

- Long-lasting protection against future infiltration

- Non-invasive, no demolition or excavation

- Eco-friendly technology

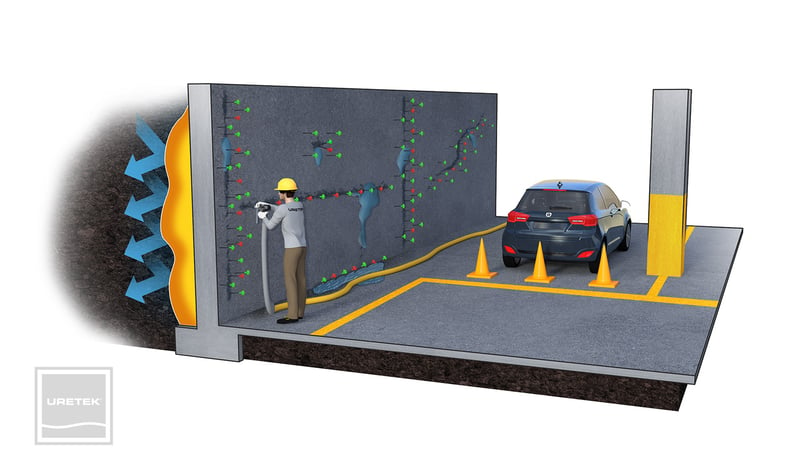

Where do we apply the Uretek Water Barrier® method?

This solution can be applied to all structures in contact with the soil, such as:

- Civil buildings: basements, cellars, lift wells, flooring

- Underground basins (even outdoors)

- Road and railway underpasses

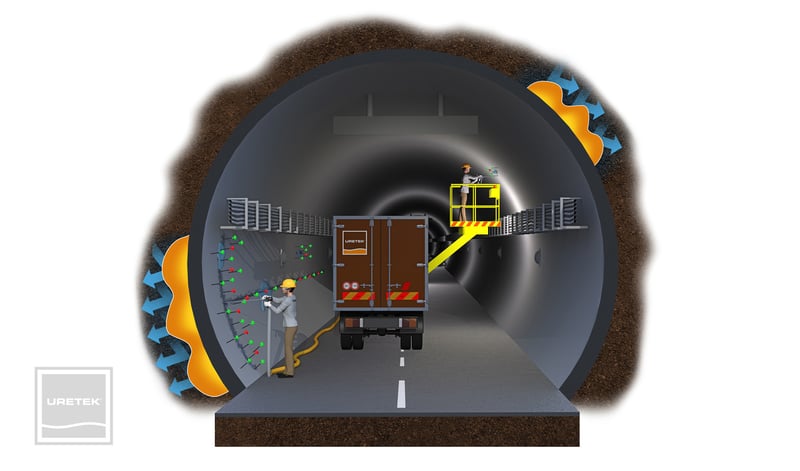

- Tunnels

- Hydraulic joints (for example, pools)

- Diaphragms

- Underground parking

- Accessible concrete tubes and wells

How does the Uretek Water Barrier® technology work?

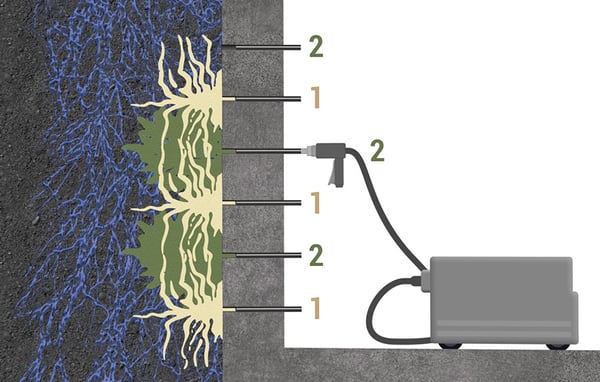

We inject a combination of expanding resin and saturating gel that fills the treated area uniformly and generates a waterproofing barrier between the structure and soil behind it. After our intervention, the walls and floors will be dry again, mould will stop forming, and the structure will no longer lose value due to this problem.

TECHNICAL SHEET

- Uretek® Resin

- Swelling pressure under maximum confinement = 40 bar

- Polymerization activated by water or humidity

- Reaction start and time can be adapted to the specific work site

- Suitable for treating cracks greater than 0.3 mm

- Uretek® Saturating Gel

- Reaction time between 1 and 3 minutes

- Suitable for treating cracks less than 0.3 mm

- Obtained by mixing 4 components, including water

1) Resina Uretek®, 2) Gel Saturante Uretek®

The Steps

1. Survey and Preliminary Inspections

We start by analysing the infiltration to understand the magnitude and causes and we provide a FREE assessment of the applicability of the Uretek Water Barrier® technology.

In fact, it is important to refer to the thickness of the structure and geometry of the nodes affected by the water (intersections with other masonry or floors) and identify discontinuities by carefully examining the structure. When the surfaces are covered and therefore not visible, possible layers of plaster, wall linings, insulation, and surface cladding should be removed.

2. The Intervention

We drill holes with a maximum diameter of 12 mm in the walls and then proceed using two components:

- a special expanding resin with high soil penetrating power. With its expansion capacity up to 30 times the original volume, it fills large voids.

- a saturating gel, which is very fluid and stable over time. It solidifies in about a minute, filling smaller voids.

After quickly preparing the equipment, we begin to drill holes with a diameter of 12 mm following a regular grid pattern. The holes are then fitted with particular injectors that serve to insert the resin and gel in the soil behind the wall.

With special pumps designed by Uretek®, we inject the expanding resin into the soil, followed by the saturating gel until it seeps out of the structure, guaranteeing that the micro voids in the terrain behind the masonry have been filled completely.

3. Plastering and Finishing

After the injections, we remove the tubes and seal the holes with a finishing resin and caps we have designed. If necessary, we apply new waterproof plaster.

See how we have resolved issues

We are close to you and we work wherever in the world our professionalism is needed.

We are familiar with your area and bring with us multinational experience.