MONITORING & CONTROL

The importance of structural monitoring.

We always focus on the safety and the precision of our interventions. We support the application of our technologies with specific monitoring systems for the structures being restored.

Standard Essential Monitoring

All our consolidation interventions for foundations and floor lifts involve a standard monitoring system that enables the structure to be restored safely and under control.

This system involves:

- Local laser monitoring consisting of a laser head and series of receivers. These receivers may be installed on the walls of the structure being consolidated or on the flooring being lifted. With an accuracy of 0.5 mm and continuous measurement, they allow for real-time verification of the reaction or lift of parts of the structure.

- Wi-Fi monitoring of the amount of resin injected. Using a tablet connected via Wi-Fi to our work-truck, we record the precise volumes of resin being injected into the soil, thereby ensuring that the project indications are respected.

- Penetration tests made before and after the consolidation allow us to verify the improvement of the mechanical properties of the soil.

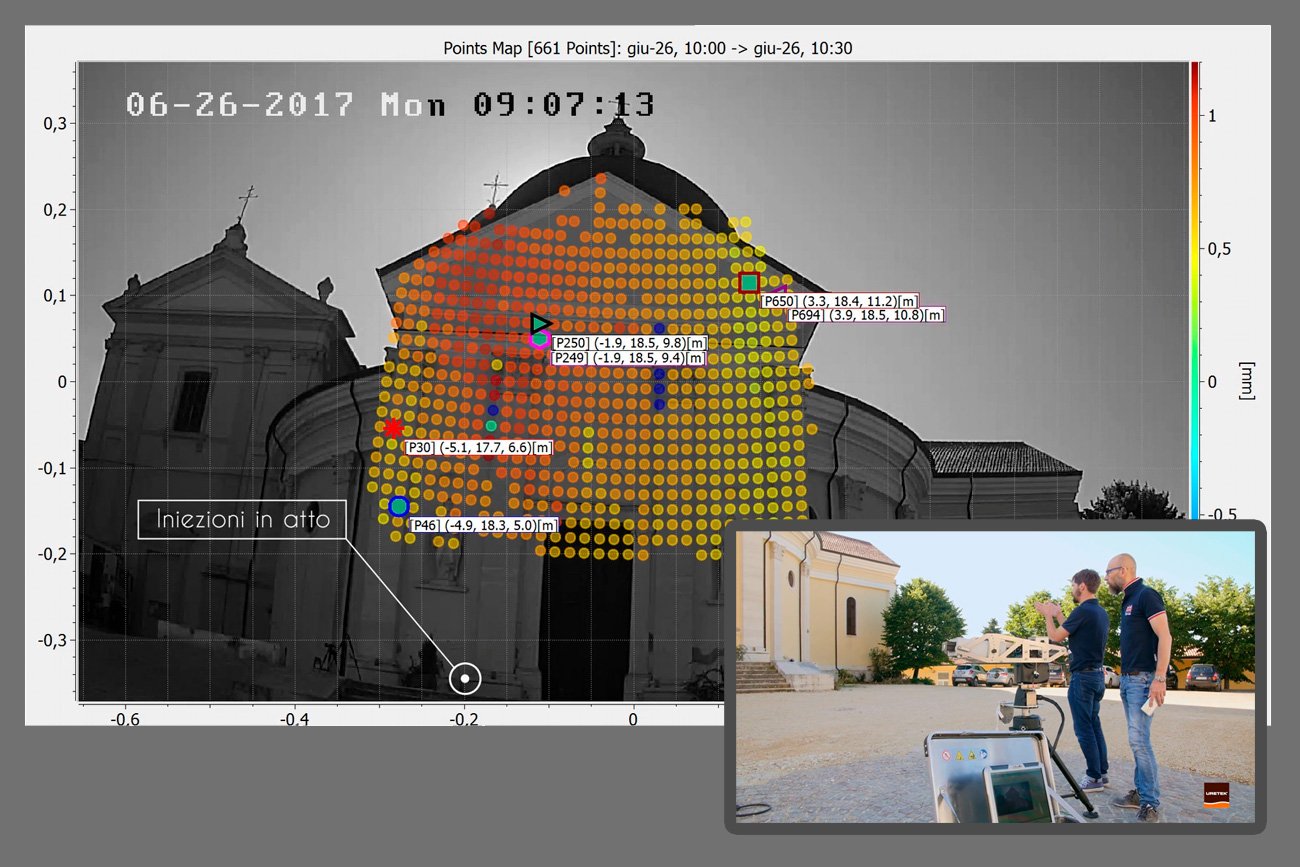

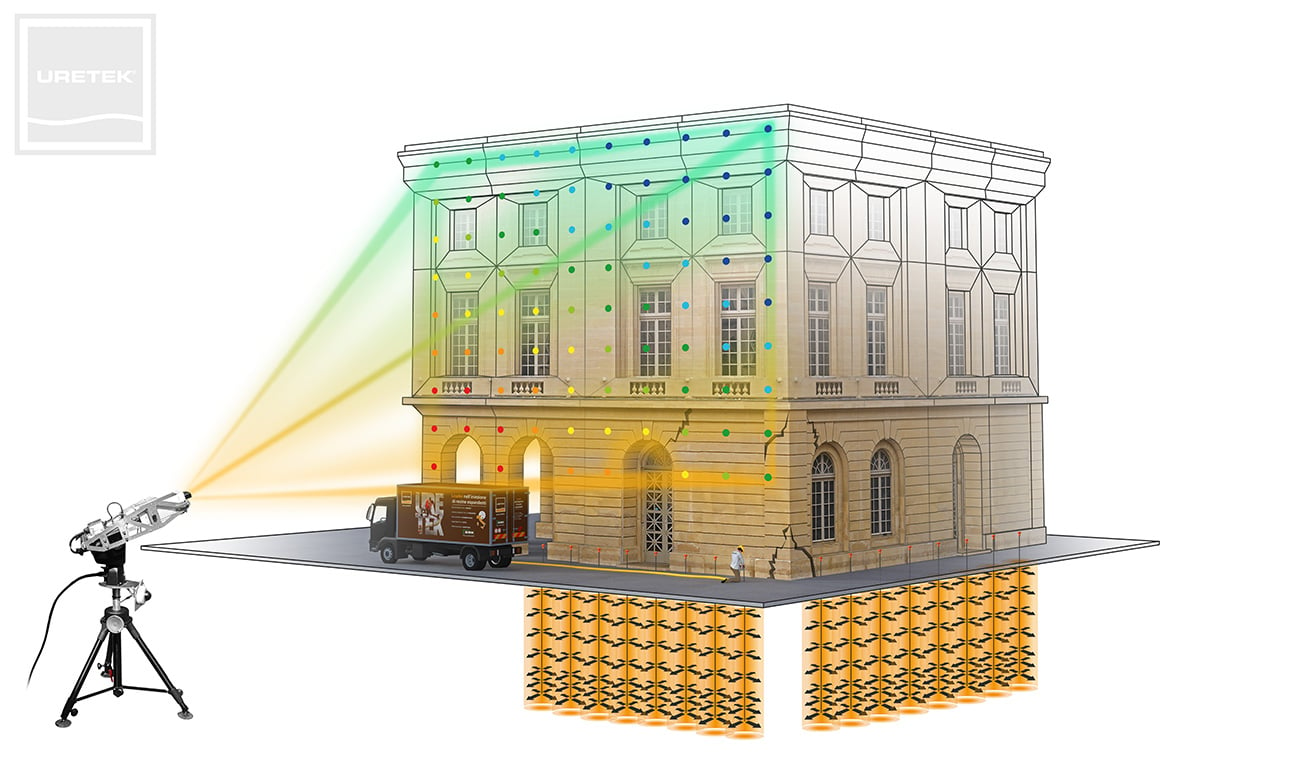

Overall radar monitoring of structures

We monitor the overlying structure during the entire injection process with particular 3D radar technology.

We scan hundreds of points on the structure walls and monitor their eventual displacement in real time with sub-millimetre accuracy.

In subsoil consolidation interventions, we use 3D radar to verify the lift at all points of the structure (the lift indicates compaction of the soil).

When subsidence of the entire structure or part of it is involved, 3D radar allows us to control the size of displacement with surgical precision, ensuring that such movements are not detrimental to the building itself.

The 3D radar system is easy to install, does not require targets to be installed on the building, may be used in any level of light or weather conditions, and may also be situated at large distances.

Fields of application:

3D radar technology may be applied to monitor:

- foundation lifts in any type of building;

- bulging of retaining walls, riverbank walls, port piers or wharfs;

- lifting of roads and industrial flooring.

Monitoring with three-axis inclinometers

We use this monitoring system in the railway sector above all, because it allows for extremely precise control in real time from the track bed when injecting resin with a limited expansion.

We install Senceive® three-axis inclinometers on the extrados or on the centre line of the sleepers using a special glue and without blocking regular rail traffic in any way. The inclinometers are connected together using a Wi-Fi module. They send the recorded data to a Flatmesh® platform, which the operator can access using a computer or tablet. They are placed at regular intervals along the length of the track and, by measuring the inclination of the three Cartesian axes, they provide information about the track gradient, crosslevel, the deviation in crosslevel, and the crookedness of the track bed.

Remote crack monitoring

The ‘Easy Crack Monitor’ system enables accurate, automatic monitoring of cracks, and the data can be read in real time on the dedicated website or a smartphone.

The system consists of a control unit, one or more crack gauges (which can also be expanded later), and an Internet monitoring area.

The crack gauges ensure accuracy on the order of 0.1 mm, detect crack displacements in two perpendicular directions, and have a small footprint.

The system can also send alert messages via email or SMS if the instruments detect deformations above a certain threshold.

Looking for underground utilities

With this technology, we can investigate the ground affected by our intervention, checking for cavities or pipes.