THE PROBLEM

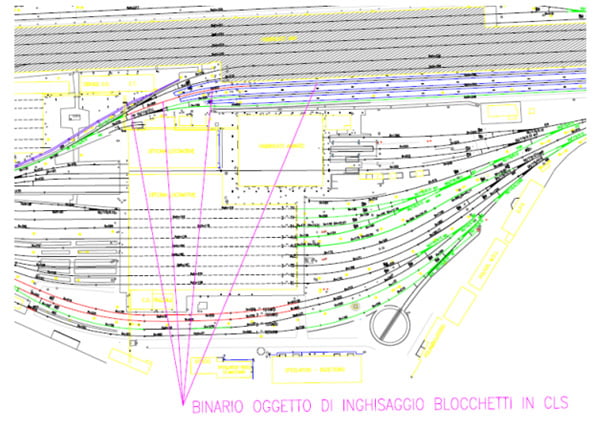

The intervention is necessary to restore the stability of no. 81 blocks in reinforced concrete prefabricated inside their seat (reinforced concrete floor), in fact when the track is unloaded the block is in the highest position with respect to the seat (reinforced concrete floor), while when the train passes the blocks are lowered inside the seat by more than 10 mm.

Customer needs

It was necessary to intervene quickly to make the railway safe, but impacting as little as possible on railway traffic.

Why the Uretek solution was chosen:

- Speed

Careful planning and programming of the times allowed the work to be completed in just a few days; - Non-invasive

The intervention proposed by Uretek did not require excavations or masonry work, and it did not dirty the area or produce waste; - Localized work

The Uretek team delimited the work area, allowing regular work activities to continue; - Continuous monitoring of the work

Both during and after the intervention, the activities were subject to control by highly qualified personnel using advanced laser technology; - Application of the exclusive Uretek Deep Injections® technology

which, thanks to the special expanding resin Uretek Geoplus®, compacts the ground and stabilizes the structures at a high swelling pressure; - Respect for the environment

the above-ground mixing of Uretek® resins generates an inert final product, which does not release eluates into the ground and any aquifers present. - Uretek is qualified by SNCF WHO RECOGNIZES ITS KNOW-HOW IN THE RAILWAY SECTOR VALID UNTIL JANUARY 2025.

- Uretek is associated CIFI, ITALIAN RAILWAY ENGINEERING COLLEGE; MAFEX, SPANISH RAILWAY ASSOCIATION and AETOS, SPANISH ASSOCIATION OF TUNNELS AND METROPOLITAN WORKS.

THE SOLUTION

Installation of Geoplus structural resin with Uretek technology at nr. 81 blocks of support points of as many sleepers / blocks of reinforced concrete. prefabricated 45 x 25 x h 25 cm which are partially drowned in a reinforced concrete slab, on the railway site in question.

INTERVENTION IN DETAIL

The work cycle consisted of

- Perimeter sealing: according to the regularity of the surfaces, using suitable putty paste;

- Laying of the resin; given the size of the space to be filled, it was injected (also by means of small holes made in the reinforced concrete sleeper / block).

Checks and verifications

Reliefs with comparator. During the resin injection operations, in order to check the behavior of the structure with regard to vertical displacements, a centesimal comparator was used. In the early stages of injection, the expulsion of the water present between the sleeper itself and its housing in the floor was found. Following the injection, a movement of the sleeper was found, at the passage of a convoy, between 1/10 and 2/10 of mm. Before the intervention, the movements were several millimeters.