The railway embankment, built about 150 years ago, consists of a stone fill in a trench previously excavated at a depth of about 13.0 m below the present railway.

THE PROBLEM

During work to lay a gas pipeline under the embankment, a tunnel with a diameter of 0.65 m was excavated by drilling into the subsoil using HDD (Horizontal Directional Drilling) technology. During the construction of the tunnel and the insertion of the pipe, subsidence was discovered under the railway. Work was halted pending the safe restoration of the work site.

Customer needs

It was necessary to work quickly to secure the railway and restart work to install the gas pipe, impacting railway traffic as little as possible.

Why the Uretek solution was chosen:

- Speed

Careful planning and programming of the times allowed the work to be completed in just a few days; - Non-invasive

The intervention proposed by Uretek did not require interruption of railway traffic, and it did not dirty the area or produce waste; - Continuous monitoring of the work

The activities were subject to real-time control using laser technology; - Application of the exclusive Uretek Deep Injections® technology

With the special Uretek Geoplus® expanding resin with high swelling pressure, the soil is compacted and the structures stabilized; - Respect for the environment

Above-ground mixing of the Uretek® resin creates a final inert product that does not release solvents into the soil or possible water tables in the area. - Uretek is qualified in the special category LOC001 (SQ011 QUALIFICATION SYSTEM ‘CIVIL WORKS AT THE RAILWAY SITE’) and by SNFC for know-how in the railway sector.

THE SOLUTION

With careful 3D finite element analysis, we identified the areas most affected by the excavation of the tunnel, where our intervention was concentrated to stabilize the initial situation and prevent any future subsidence. The control and monitoring activities showed the full success of the operation, allowing the pipe installation to be completed.

Observations

From the discovery of the subsidence to the end of the operation to secure the construction site, railway traffic continued but the speed of the trains was reduced to about 20 km/h.

THE INTERVENTION IN DETAIL

Subsidence

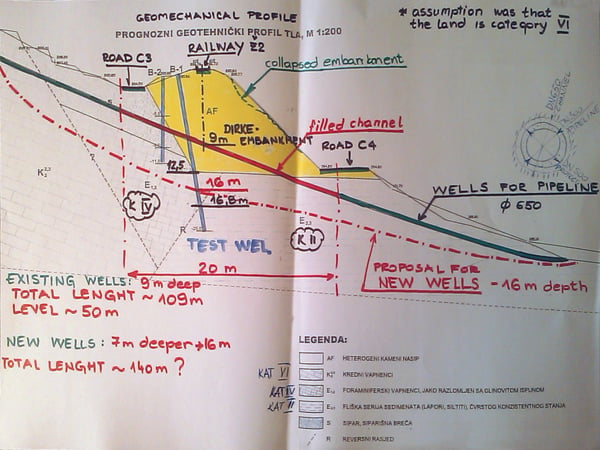

In addition to the railway line, the embankment, which has a base about 30 metres wide, supports two roads, one located on the north side of the railway and the other on the south side. The geotechnical report prepared following a commissioned study, showed that the embankment was built with homogeneous stone materials, most likely with irregularly shaped stone of the size of 5-20 cm without using fine material. This type of structure implies the presence of notable voids.

According to data collected from drilling and our experience with similar building structures on the Zagreb-Rijeka line, we estimated a void index of 35% and 30% for the upper and lower parts of the embankment, respectively. The most likely cause of the failure was the settling of the pipeline tunnel due to vibrations associated with the excavation. An attempt had been made in the past to strengthen the embankment affected by the subsidence once the protective pipe was removed, but this was unsuccessful because the voids between the stones were too large to hold the concrete. In the meantime, the embankment continued to drop (about 5 cm/week). To compensate, the railway was supported many times over short intervals with new stone.

PLAN OF THE INTERVENTION

Our Intervention

The embankment drilling was done by a specialized company that inserted a coating with a diameter of about 110 mm. We then laid the injection ducts, wrapped in a single bundle, within the coating. To be able to reach the predetermined injection point precisely, the pipes had different lengths, similar to organ pipes. For each injection, we therefore had to use a disposable conduit 12 mm in diameter and make the injections in an alternating series to allow the extra pressure due to the swelling of the resin to dissipate in the soil. After each bundle of ducts was laid, we proceeded to remove the coating.

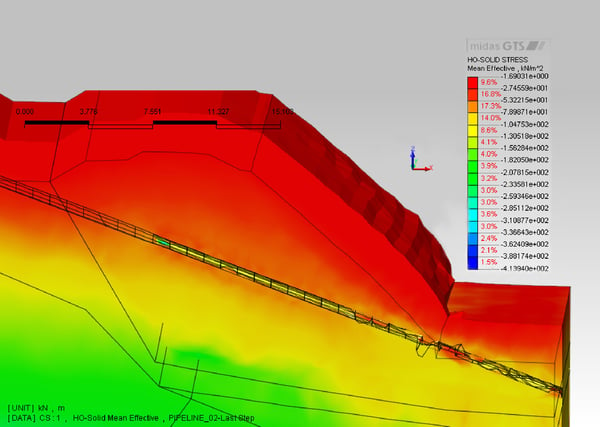

3D Finite Element Analysis

To analyse the volume of soil predominantly affected by the drilling to lay the pipe, we conducted a 3D FEM analysis, which showed how the finite elements would behave based on generate complex geotechnical models. The analysis highlighted the areas most affected by the excavation of the tunnel, where our injections were concentrated to avoid future subsidence. Overall, including the drilling and injection phases, the whole operation took about 15 days.