THE PROBLEM

On the railway high speed line two sections of the embankment presented problems of instability.

Customer needs

It was necessary to intervene quickly to make the railway safe, but impacting as little as possible on railway traffic.

Why the Uretek solution was chosen:

- Speed

Careful planning and programming of the times allowed the work to be completed in just a few days; - Non-invasive

The intervention proposed by Uretek did not require excavations or masonry work, and it did not dirty the area or produce waste; - Localized work

The Uretek team delimited the work area, allowing regular work activities to continue; - Continuous monitoring of the work

Both during and after the intervention, the activities were subject to control by highly qualified personnel using advanced laser technology; - Application of the exclusive Uretek Deep Injections® technology

which, thanks to the special expanding resin Uretek Geoplus®, compacts the ground and stabilizes the structures at a high swelling pressure; - Respect for the environment

the above-ground mixing of Uretek® resins generates an inert final product, which does not release eluates into the ground and any aquifers present. - Uretek is qualified by SNCF WHO RECOGNIZES ITS KNOW-HOW IN THE RAILWAY SECTOR VALID UNTIL JANUARY 2025.

- Uretek is associated CIFI, ITALIAN RAILWAY ENGINEERING COLLEGE; MAFEX, SPANISH RAILWAY ASSOCIATION and AETOS, SPANISH ASSOCIATION OF TUNNELS AND METROPOLITAN WORKS.

THE SOLUTION

The consolidation intervention was carried out by injecting expanding mixtures into the body of the railway embankment in order to improve the parameters of resistance and deformability and concerned the foundation soil of the platform of the tracks, the overall development of the intervention is equal to 490 m of embankment.

THE INTERVENTION IN DETAIL

USE OF URETEK DEEP INJECTIONS TECHNOLOGY WITH URETEK MULTIPOINT® INJECTION SYSTEM

The Multipoint® injection system allows you to maximize the injection points within the volume of soil treated by limiting the number and diameter of the perforations as much as possible.

The injection tubes consist of steel cannulas with an external diameter of 12 mm with a blind bottom which are reinforced with millimeter holes on the side surface. The diameter and position of the holes depend on the soil, the characteristics of the mixture and the injection parameters.

DRILLING

The perforations, with a diameter of 26 mm, were made with manual electric rotary percussion punches with maximum impact energy equal to 11 Joules, maximum rotation speed of 360 RPM and maximum impact frequency of 2800 strokes / minute. The inclination of the drilling was measured using a level mounted on the bottom of the perforator.

INJECTION PIPES

The injection pipes were laid in the hole using percussion tools up to the project depth. The maximum length of the pipes has been kept less than 3.50 m, in order not to interfere with the electrical power supply line of the track. The pipes that have been placed at greater depths than their length have been joined with special sleeves fixed with electric pressure pliers, during laying in the ground. At the end of the injections, the tubes were cut just below the ground.

INJECTIONS

The injections were carried out with a gun which, by engaging with a hole, introduced the resin previously mixed into a special premixing chamber into the underground duct. Due to the proximity of the tracks, the injection pressure has been reduced to a minimum. In any case, the injection was continued until the projected quantities or thresholds managed by the monitoring system were reached.

INTERVENTION AREAS AND INJECTION SCHEME

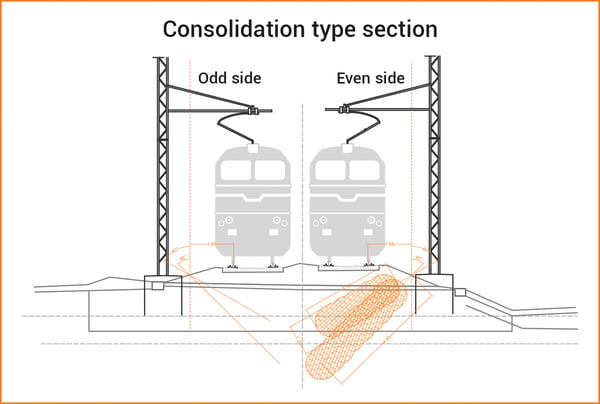

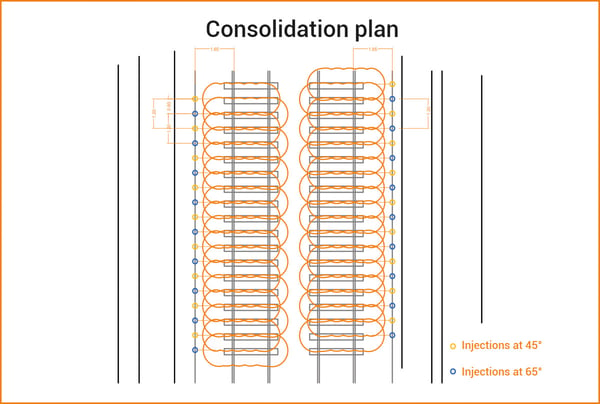

The scope of the intervention was divided into 4 different construction site areas that were treated simultaneously by 4 teams. The intervention was carried out according to the following typological scheme.

Mesh of alternating inclined injections with a distance of 1.2 m and inclinations of 45 ° (deep) and 60 ° (superficial) respectively with respect to the vertical, made on the side of the railway embankment for each track.