THE PROBLEM

The structure originally dates back to the late 19th century and was built in solid brick masonry. The foundation is in brick with a laying surface placed at an indicative depth of about 1.5 - 1.8 m from the ground level.

The intervention has a provisional character as it is preparatory to the construction of a definitive foundation slab based on micropiles.

Customer needs

It was necessary to intervene quickly to make the railway safe, but impacting as little as possible on railway traffic.

Why the Uretek solution was chosen:

- Speed

Careful planning and programming of the times allowed the work to be completed in just a few days; - Non-invasive

The intervention proposed by Uretek did not require excavations or masonry work, and it did not dirty the area or produce waste; - Localized work

The Uretek team delimited the work area, allowing regular work activities to continue; - Continuous monitoring of the work

Both during and after the intervention, the activities were subject to control by highly qualified personnel using advanced laser technology; - Application of the exclusive Uretek Deep Injections® technology

which, thanks to the special expanding resin Uretek Geoplus®, compacts the ground and stabilizes the structures at a high swelling pressure; - Respect for the environment

the above-ground mixing of Uretek® resins generates an inert final product, which does not release eluates into the ground and any aquifers present. - Uretek is qualified by SNCF WHO RECOGNIZES ITS KNOW-HOW IN THE RAILWAY SECTOR VALID UNTIL JANUARY 2025.

- Uretek is associated CIFI, ITALIAN RAILWAY ENGINEERING COLLEGE; MAFEX, SPANISH RAILWAY ASSOCIATION and AETOS, SPANISH ASSOCIATION OF TUNNELS AND METROPOLITAN WORKS.

THE SOLUTION

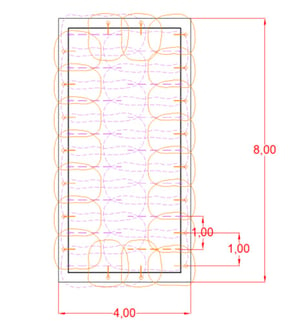

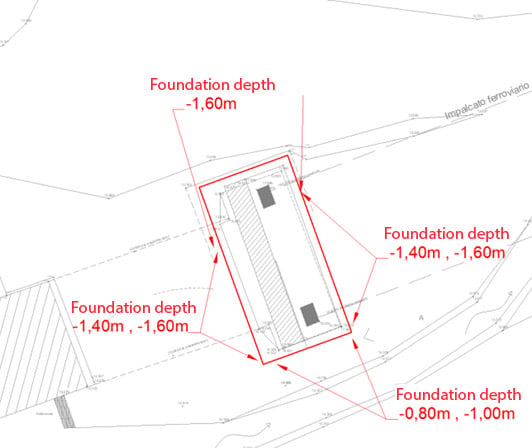

The consolidation intervention concerned the ground below the foundation of a railway bridge pylon (Municipality of Ripabottoni (CB) at km 60 + 465 of the Ripabottoni - Campolieto section, belonging to the Termoli - Venafro line), by means of injections of Geoplus expanding resin with Uretek Deep Injections technology, performed on a surface of about 4.0 X 8.0 m..

THE INTERVENTION IN DETAIL

APPLIED TECHNOLOGY

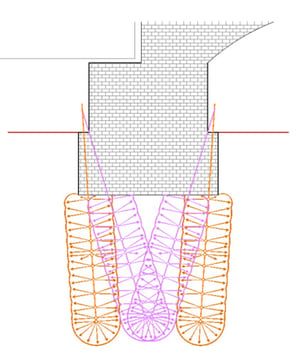

The intervention involved the use of the Uretek Multipoint injection system. The main features of the system are the following:

Creation of a very dense and regular injection mesh in the ground;

Localize the mixture near the injection sources avoiding dispersions or discontinuity of treatment.

Drills were carried out along the perimeter of the building with different inclinations in order to reach the volume of soil under the foundation. The center distance of the perforations was 1.00 m for the perimeter ones of the artifact and also 1.00 m but placed in the middle of the previous center distance for the inclined ones.

The foundation is made up of a main core in solid bricks and curbs and completion elements in reinforced concrete. superimposed on the masonry structure. During the drilling, the tax depth of the foundation was measured, varying between -0.80 m and -1.60 m from the extrados of the same, outcropping at the ground level.

LASER MONITORING

During the resin injection operations, in order to monitor any vertical displacements of the structure, laser instrumentation was used with a precision of ± 0.5 mm.

PENETROMETRIC TESTS

The positive outcome of the intervention was checked with comparative dynamic penetrometric tests that allow you to appreciate the increase in the mechanical parameters of the injected soil volumes.

In particular, two pre-injection tests and two post-intervention tests were performed. The post-intervention tests resulted in instrumental refusal immediately below the foundation's tax plan.