The building, designed for residential use, was built in 1994. It has five floors above ground an and underground area. The foundations of both the building and garage consist of ground beams in reinforced concrete.

THE PROBLEM

Following the earthquake on 6 April 2009, the building showed several types of damage. Prior to a full restoration, we analysed the current and future loads. According to the design, the geotechnical parameters of the layer consisting of silty-sandy clay (Cu = 0.67 kg/cm2) needed to be increased by 35% in the area identified for the consolidation.

Customer needs

The customer requested a quick, long-lasting intervention to consolidate the foundations that respected the standards for seismic safety.

Why the Uretek solution was chosen:

- Speed

Careful planning and programming of the times allowed the work to be completed in a relatively short time; - Competitive prices;

- Non-invasive

The intervention proposed by Uretek did not require excavations or masonry work, and it did not dirty the area or produce waste; - Continuous monitoring of the work

Both during and after the intervention, the activities were subject to real-time control by highly qualified personnel using advanced laser technology; - Application of the exclusive Uretek Deep Injections® technology

With the Uretek Geoplus® expanding resin with high swelling pressure, the soil is compacted and the structures stabilized; - Respect for the environment

Above-ground mixing of the Uretek® resin creates a final inert product that does not release solvents into the soil or possible water tables in the area.

THE SOLUTION

We chose to apply the Uretek Deep Injections® technology which, with injections of the special Uretek Geoplus® expanding resin, consolidated the ground in two distinct but complementary phases:

- PHASE 1 – Surface compaction:

We made injections in the intrados of the foundations to improve the geomechanical characteristics of the terrain and fill the larger voids present in the foundation-soil interface. - PHASE 2 – Deep consolidation

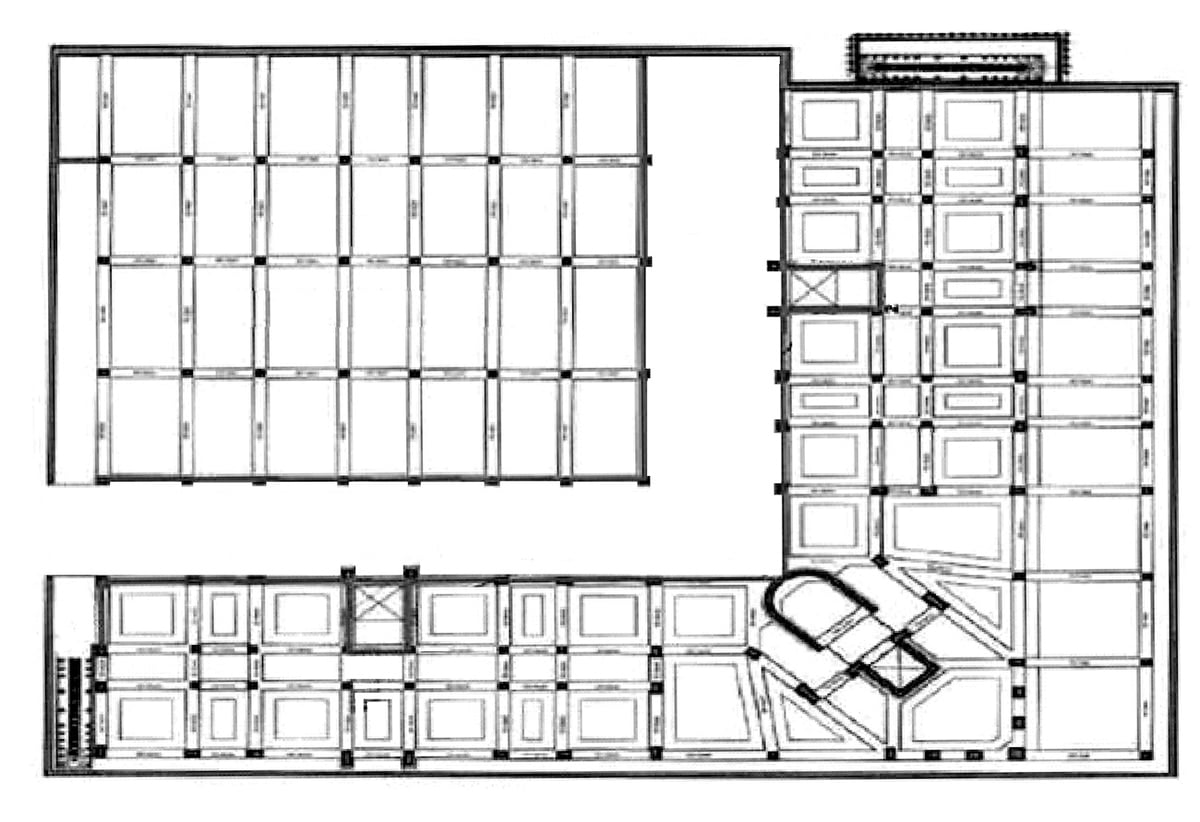

In the soil affected by the loads transmitted by the building, we made injections at another three depths. Overall, we consolidated the soil underlying 117.0 m of continuous foundation.

THE INTERVENTION IN DETAIL

The Investigations

- The soil:

Our investigations and the geological report showed that the foundation soil below the man-made elements (from ground level down to a depth of about 2.00 metres) consisted of sandy loam with clay from 2.00 m to 6.00 m below ground level and silty sand with clay from 6.00 m to 11.5 m below ground level. - The foundations:

With respect to the working plane, we surveyed the base of the continuous ground-beam foundations at a depth of 1.70 m for body A and 1.00 m for body B. The width of the foundation base was 1.0–1.5 m for body A and 0.5–0.7 m for body B. - Operational phases:

We drilled holes with a 26-mm diameter in the foundation at regular intervals to a maximum depth of 3.10 m. Where the rocky substrate was closer to the surface, we drilled the holes closer together. In this way, we reached the precise volume most affected by loads on the surface.

Using hammer drills, we inserted the steel injection conduits into the holes. During the injections, we noted a lift of the structures between 1.0 mm and 2.0 mm.

We verified the success of the intervention by making 18 comparative dynamic penetration tests (9 before and 9 after injection) to measure the increase in mechanical parameters of the volumes of soil treated with injections. We made the tests with a DPM30 average dynamic penetrometer.

At the corner of body B, we also made a penetration test (test P10) during the operation to assess the improvement in soil properties due to the injection in that area. The results of the penetration tests after the injection showed that the agreed-on design objectives were reached. The number of average hits (N10) in the volume of treated soil was:

- at least 13 in the lift areas;

- at least 10 in other areas involved in the intervention.

Observations

Our intervention at the ‘Il Bosco’ block of flats is covered by a dual guarantee: a contractual guarantee provided by Uretek and an insurance guarantee provided by QBE, a premier global insurance provider. Both cover the first ten years following completion of the work.