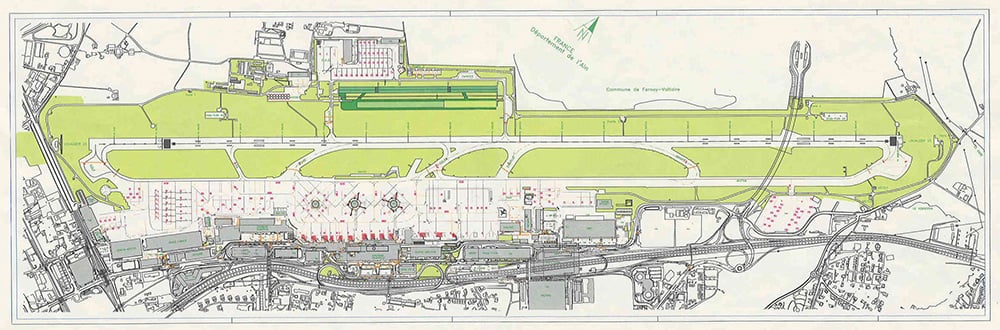

Located less than 5 kilometres from the city centre, with an average of 12 million passengers per year and 177,000 aeroplanes passing through, the Geneva Airport (Geneva Cointrin International Airport) houses the International Air Transport Association (IATA) and Airports Council International (ACI).

THE PROBLEM

Over time, aeroplane loads had led to a non-uniform subsidence of the reinforced concrete slabs in some areas of the runway and aeroplane parking areas, provoking hazards and unacceptable height differences between the slabs.

Why the customer chose Uretek:

- Speed: Careful planning and programming of the times allowed the work to be completed in a relatively short time;

- Competitive prices;

- Non-invasive: The intervention did not dirty the area or produce waste;

- Continuous monitoring of the work: The activities were subject to real-time laser control by highly qualified personnel;

- Application of the exclusive Uretek Floor Lift® technology: A special expanding resin with high swelling pressure is injected into the soil, compacting it and stabilizing the structures;

- Respect for the environment Above-ground mixing of the Uretek® resin creates a final inert product that does not release solvents into the soil or possible water tables in the area.

THE SOLUTION

We used the Uretek Floor Lift® technology, designed specifically to solve these types of problems. Injecting a special expanding resin into the soil under the concrete base of the slabs, we filled the voids and reinforced the underlying terrain. Once full contact between the paving and subgrade had been restored, the resin continued to expand, lifting the paving and recovering its flatness.

Observations

We have performed maintenance regularly on various areas of the Geneva airport runways since 1997. We consolidated the soil under the paving in various areas in 2002 and 2008, always with success.

Among the many advantages offered by the Uretek Floor Lift® technology, the possibility of using the treated area immediately after the intervention is much appreciated.

THE PROJECT IN DETAIL

The Geneva Airport was built on reclaimed swampland. Continuous aeroplane traffic with ever increasing loads had subjected the concrete slabs in the runways and parking areas to great dynamic stress that had caused differential subsidence of the soil over time. This had in turn led to the formation of depressions in the slabs and ‘steps’ between them, compromising the safety and efficiency of landing in Geneva.

Abbiamo progettato l’intervento dopo aver acquisito i dati relativi alla stratigrafia e consistenza del terreno e allo spessore e composizione delle piastre in cemento armato.

Lifting and consolidation: We continued to inject the expanding resin until the voids were completely saturated and the soil completely thickened. From this point on, the continued injections lifted the structure.

Drilling: Using handheld drills, we made holes with a diameter less than 3 cm and a spacing of 1–2 metres.

Injection: We injected the resin as a liquid, but already undergoing expansion. In just a few seconds, the chemical reaction led to an increase in volume of 10–15 times the initial state

Monitoring: On the paving and at a suitable distance from the injection zone, we positioned laser levels capable of detecting even millimetre-sized movements of the slabs. In this way, we re-established the correct planarity very precisely.

To avoid hindering normal airport operations, we often worked at night.

Our team, consisting of two specialized technicians, can treat about 1000 sq. m of paving in 5 nights.

LUC SCHOBER, Vice Director of Maintenance, Geneva Airport: ‘Uretek Floor Lift® is a quick, clean solution that guarantees a stable foundation for many years, prolonging the useful life of the runway. The teams that carried out the intervention were very efficient and know their work well. We are happy with this method and will use it again in the years to come.’