National road 49 della Pusteria crosses the valley of the same name, starting in Bressanone, in South Tyrol. It then touches the municipalities of Varna, Rio di Pusteria, Falzes, Brunico, Monguelfo, Dobbiaco, San Candido, and reaches the national border at Prato alla Drava, where it enters Austria.

THE PROBLEM

Near the town of Villa di Sotto (BZ) at about km 37 (Ponte Perca), some areas of paving showed depressions and longitudinal and transverse cracks. The causes of the subsidence were due to the difference in rigidity between the flexible and rigid paving, water infiltration with the consequent removal of fine material, and vibrations from passing vehicles.

Customer needs

The customer needed a decisive intervention that would guarantee the utmost safety over time, possibly without interrupting normal traffic.

Why the Uretek solution was chosen:

- Speed

Careful planning and programming of the times allowed the work to be completed in a relatively short time; - Competitive prices

- Non-invasive

The intervention proposed by Uretek did not require excavations or masonry work, and it did not dirty the area or produce waste; - Continuous monitoring of the work

Both during and after the intervention, the activities were subject to real-time control by highly qualified personnel using advanced laser technology; - Application of the exclusive Uretek Floor Lift® technology

This maintenance solution regenerates the deep road paving and lengthens the useful life, solving instability problems without removing the surface; - Use of the Uretek Geoplus® resin

The resin expands quickly with a high swelling pressure, remaining stable and confined to the required volume; - Respect for the environment

Above-ground mixing of the Uretek® resin creates a final inert product that does not release solvents into the soil or possible water tables in the area.

THE SOLUTION

We those the Uretek Floor Lift® technology because it thickens the deep soil using injections of polyurethane resins with a high swelling pressure. When it expands, the resins create a compacting action, which increases the rigidity of the soil. About 115.50 sq. m of road paving were consolidated. Work was carried out on the nights of 2/3 and 3/4 November 2012, with a change in the direction of one-way traffic each night.

OBSERVATIONS

A flexible and non-invasive technology such as Uretek Floor Lift® enabled intervention WITHOUT REMOVING THE SURFACE and WITHOUT BLOCKING TRAFFIC.

THE INTERVENTION IN DETAIL

The work site

We carried out the Uretek Floor Lift® recompression and consolidation in the following steps:

- Installation of road signs and a traffic signal to establish alternating one-way traffic;

- Pre-intervention seismic and penetration tests;

- Drilling of the road paving using handheld electric drills and installation of the injection tubes;

- Consolidation injections combined with laser monitoring of road surface movements;

- Post-intervention seismic and penetration tests;

- Opening traffic on the treated section of road.

Operational phases

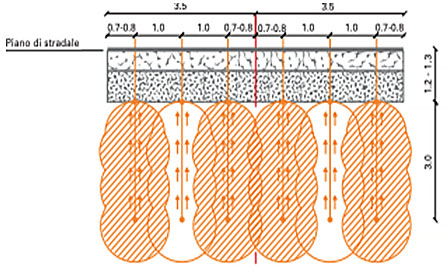

We drilled holes with a diameter of 18–26 mm through the road base and underlying subgrade, extending to an average depth of 3 metres below the road thickness. Drilling the holes at regular distances, we reached the precise ‘important’ volume. We surveyed the impost plane of the road base-subgrade at a depth of 1.20–1.30 metres below the surface.

Monitoring

We monitored the road surface during the work using laser instruments (precision equal to ±0.5 mm), which constantly detected the vertical displacement. During the injections, we detected a maximum lift of 2 mm.

Testing

We verified the success of the intervention by making 6 comparative dynamic penetration tests (3 pairs of tests before and after the intervention), which showed an enhancement in mechanical properties in the volumes of soil treated with injections. During the work we also applied a geophysical method to assess the rigidity of the ground beneath the foundations. The Uretek Seismic Test (European patent) is a system of geophysical tests to investigate the layers of the ground underlying the foundation without being influenced by the more rigid surface layers, known as "ghost layers". The increase in shear wave velocity detected in this layer demonstrated the improvement of the treated soil.